1. Solution Mining

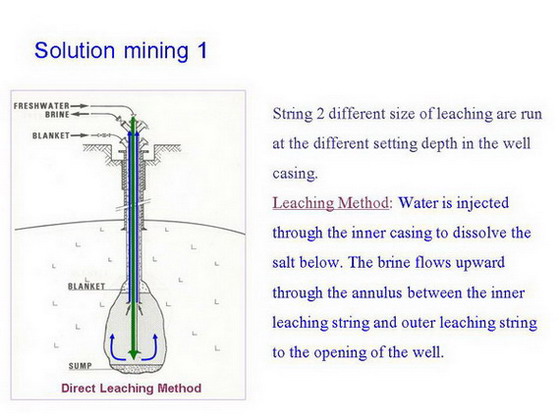

It's to inject freshwater to dissolve the rock salt. Dissolved brine obtained will return by pressure to the opening of the well.

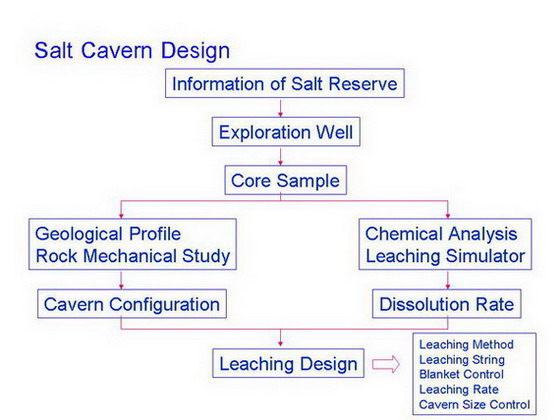

We produce "purified salt" with modern technology that is able to utilize rock salt efficiently and with high safety. The solution mining requires geological data, properties of soil, rock formation, salt formation, and chemical properties of salt deposits.

Once the caverns grow to their designed size, after the production, the wells will be closed holding full level of saturated brine while the pressure inside is maintained at all times. Overseas, salt caverns are often used to store oil, petroleum gas or non-water soluble wastes and nuclear wastes.

Environmental Impact Assessment (EIA)

- Preventive measures to monitor the Environmental Impact

- Tree planting around the area

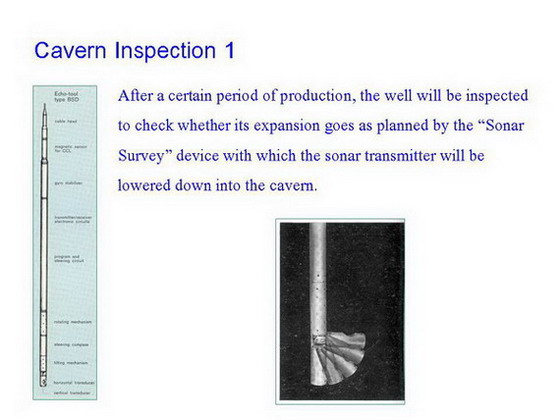

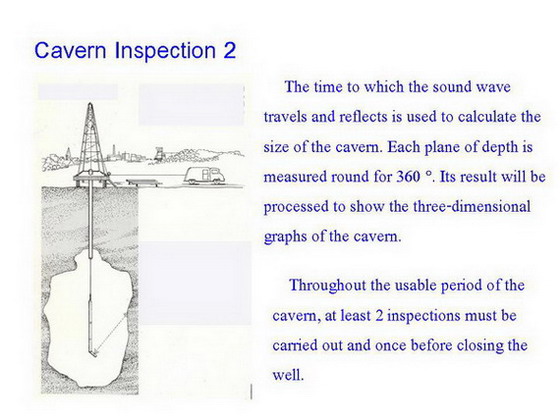

- Cavern inspection by Sonar Survey

- Level check around mining concession area

- Subsidence survey will be done every 6 months by the Department of Mining Resources officers.

- Surface water and soil analysis every 2 months